AIAG-VDA FMEA

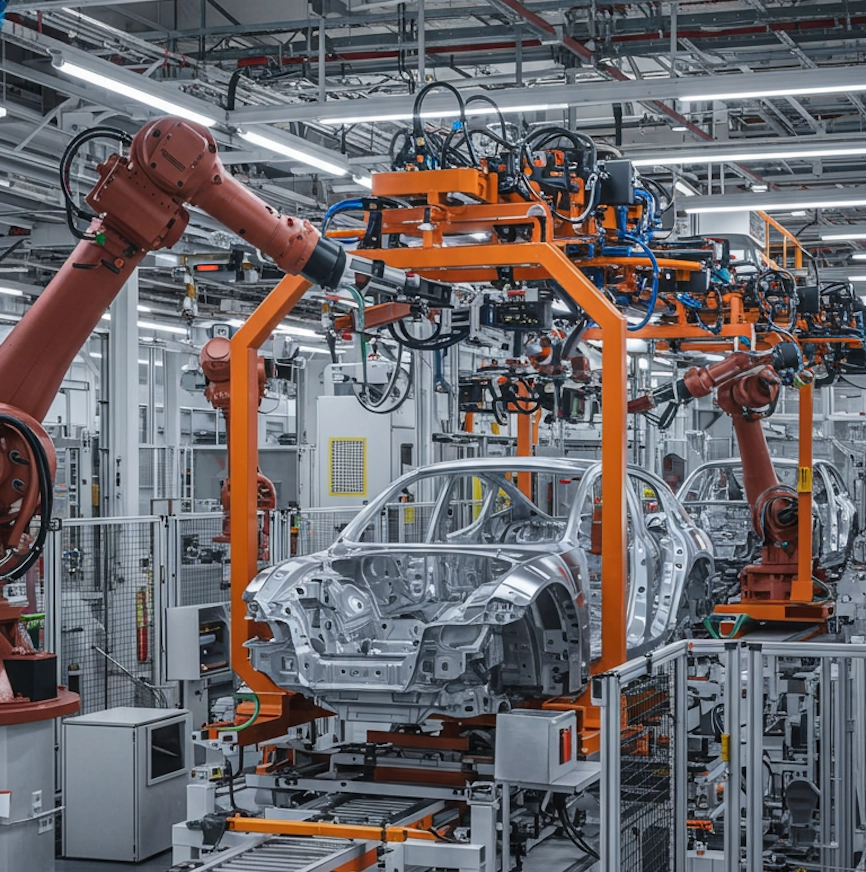

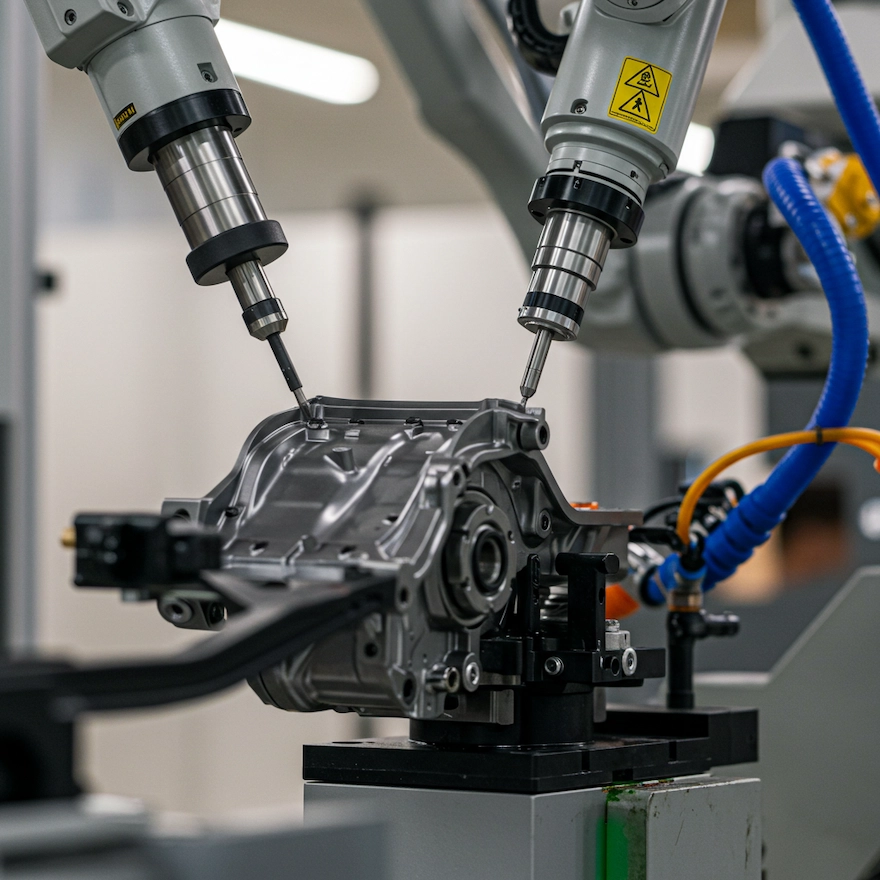

Master the definitive AIAG-VDA FMEA methodology for superior risk analysis automotive. This premier program covers design FMEA and process FMEA, integrating APQP and IATF 16949 requirements. Learn technical risk reduction and failure prevention strategies to improve product reliability. Implement defect prevention techniques, process stability analysis, and diagnostic system response for effective severity occurrence detection and failure chain analysis.

Focus of AIAG-VDA FMEA Training: Expert Risk Management for Malaysian Industry Excellence

Prevent failures, reduce costs, prioritize risk collaboratively.

Our Mission & Vision

Provide effective training and solutions that grow competitiveness of our clients.

Highlights of AIAG-VDA FMEA Training: Expert Risk Management for Malaysian Industry Excellence

Master risk mitigation optimization with our AIAG-VDA FMEA expertise.

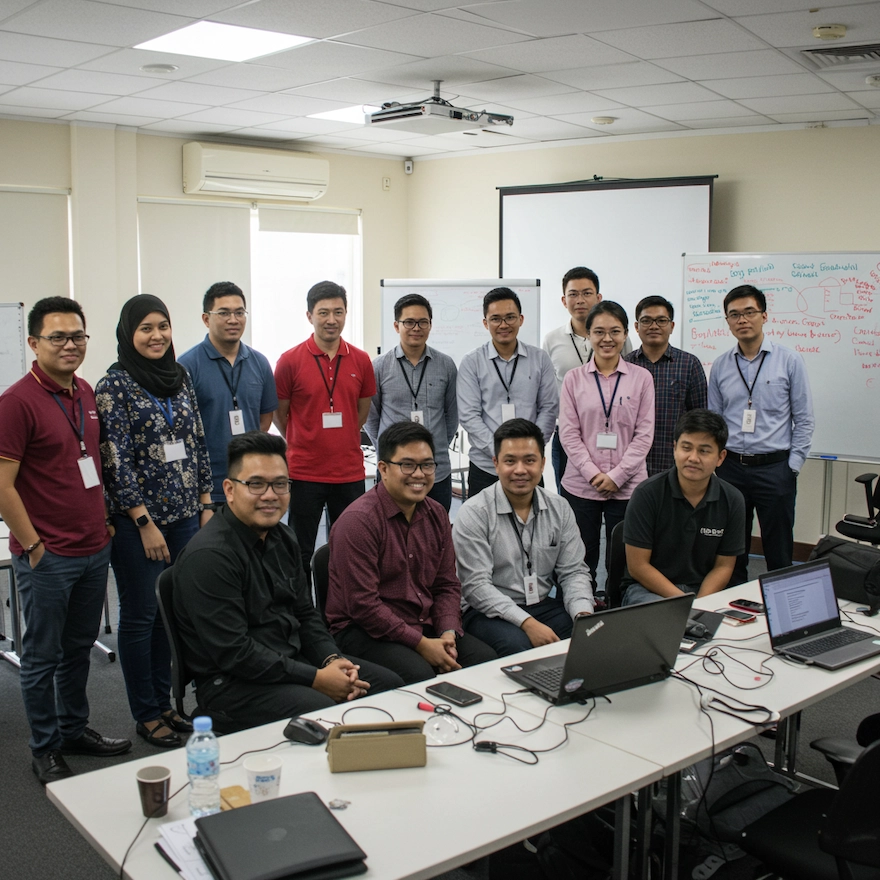

This program uniquely blends AIAG-VDA FMEA expertise with unmatched practical relevance. Led by automotive quality professionals, it uses real-world automotive examples and interactive failure analysis workshops. You will master risk mitigation optimization and defect elimination techniques through hands-on FMEA development. This ensures immediate skills for manufacturing efficiency enhancement and quality cost reduction, driving proven performance improvements beyond theoretical courses.

Optimize risk mitigation with our expert-led AIAG-VDA FMEA training. Gain practical skills through hands-on workshops and real-world case studies. Secure your competitive edge now.

Frequently Asked Questions: 3C

FAQ 1. What COMPETENCY and skills will I gain from this training?

FAQ 2. Can the training be tailored or CUSTOMISED to our organizations specific needs?

FAQ 3. Will I receive a recognized qualification or CERTIFICATE?

Competency

Customization

Certificate

Master the harmonized AIAG-VDA FMEA approach.

Master the harmonized AIAG-VDA FMEA method to proactively prevent failures, reduce costs, and prioritize risk. Enhance design and process controls to improve quality and strengthen collaboration.